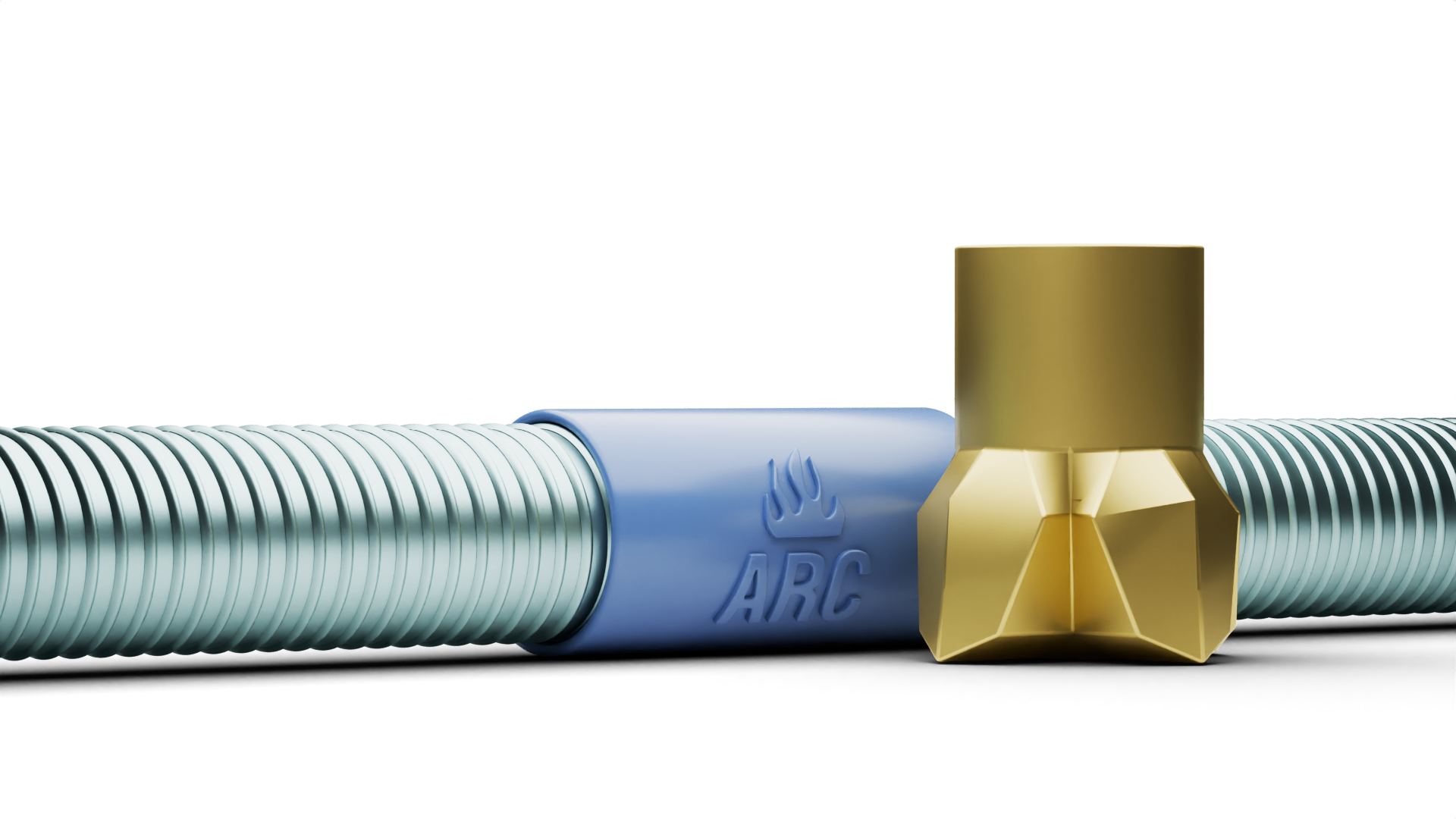

FRP rockbolts, also known as fiber-reinforced polymer (FRP) rock bolts or glass fibre reinforced polymer (GFRP) rock bolts, are a type of support system used in underground mining, tunnelling, and civil engineering projects to reinforce and stabilize rock formations.

FRP rockbolts are made of a composite material consisting of continuous glass fibers or other high-strength glass fibers embedded in a polymer resin matrix, typically a thermoset resin like polyester, vinyl ester, or epoxy.

Due to the good chemical properties of the special resin and the high-strength of the glass fiber, coupled with the special manufacturing process, which determined that the FRP rock bolt has the incomparable performance advantages of other materials.

FRP rockbolts possess high tensile strength, often comparable to or exceeding that of steel rockbolts. This high strength enables FRP rockbolts to provide excellent support and reinforcement to rock structures, ensuring their stability and integrity.

FRP rockbolts are highly resistant to corrosion, making them suitable for use in corrosive environments such as mining, tunneling, and underground construction. They do not rust or deteriorate like steel rockbolts, ensuring long-term performance and reducing the need for costly replacements.

FRP rockbolts are significantly lighter than steel rockbolts, typically weighing about 25% of their steel counterparts. This lightweight nature makes handling, transportation, and installation of FRP rockbolts easier and more efficient, reducing labor costs and improving productivity.

FRP rockbolts are electrically non-conductive, providing an added safety benefit in environments where electrical hazards are present. They eliminate the risk of electrical current traveling through the rockbolt and potentially causing harm to workers or equipment.

FRP rockbolts are highly durable and have a long service life. They can withstand the harsh conditions encountered in rock reinforcement applications, including stress, vibration, and chemical exposure. The durability of FRP rockbolts reduces the need for frequent replacements and maintenance.

FRP rockbolts can be easily installed using conventional drilling and anchoring methods. They can be cut to desired lengths on-site and installed using resin or mechanical anchors. The ease of installation reduces the time and effort required for rock reinforcement tasks.

FRP rockbolts exhibit a certain degree of flexibility compared to steel rockbolts. This flexibility allows them to accommodate minor rock movements and deformations without losing their structural integrity. The flexibility also helps in distributing the load evenly along the rockbolt length.

FRP rockbolts are resistant to a wide range of chemicals, including acids, alkalis, and solvents. This chemical resistance makes them suitable for use in environments where exposure to aggressive chemicals is common, such as in mining and industrial applications.

FRP rockbolts have excellent fatigue resistance, making them suitable for applications where cyclic loading is present. They can withstand repeated stress cycles without significant degradation in their performance, ensuring long-term stability of the reinforced rock structure.

FRP rockbolts are an environmentally friendly alternative to steel rockbolts. They are made from non-corrosive and non-toxic materials, reducing the environmental impact associated with corrosion and leaching of metals into the surrounding environment.

While the initial cost of FRP rockbolts may be higher than steel rockbolts, their long-term cost-effectiveness is significant. The durability, corrosion resistance, and reduced maintenance requirements of FRP rockbolts result in lower lifecycle costs compared to steel alternatives.

FRP rockbolts can be used in various rock reinforcement applications, including mining, tunneling, slope stabilization, and underground construction. They are suitable for different rock types and geological conditions, providing versatile solutions for rock support and stabilization.

| Unit | Hollow Rockbolt | Self-drilling Rockbolt | |||||

|---|---|---|---|---|---|---|---|

| Diameter | mm | 12/25 | 28/12 | 32/12 | 25/12 | 28/12 | 32/12 |

| External | mm | 25 | 28 | 32 | 25 | 28 | 32 |

| Cross-Section | mm2 | 345 | 450 | 563 | 345 | 450 | 563 |

| Thread Distance | mm | 10 | 10 | 10 | 12.7 | 12.7 | 12.7 |

| Thread Direction | Right | Right | Right | Left | Left | Left | |

| Tensile Load | kn | 230 | 300 | 380 | 250 | 330 | 400 |

| Tensile Strength | MPa | 650 | 650 | 650 | 650 | 650 | 650 |

| Torsion | Nm | 80 | 110 | 200 | 120 | 200 | 250 |

ARC FRP products come with an in-house test certificate documenting performance, quality, and compliance based on internal testing and evaluations.

Download