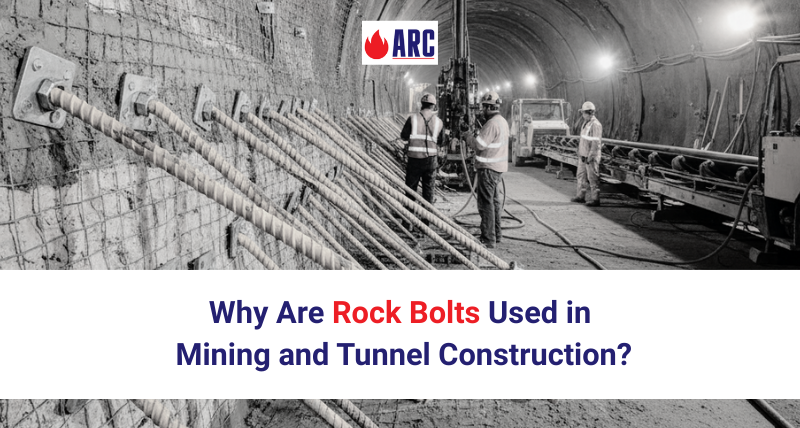

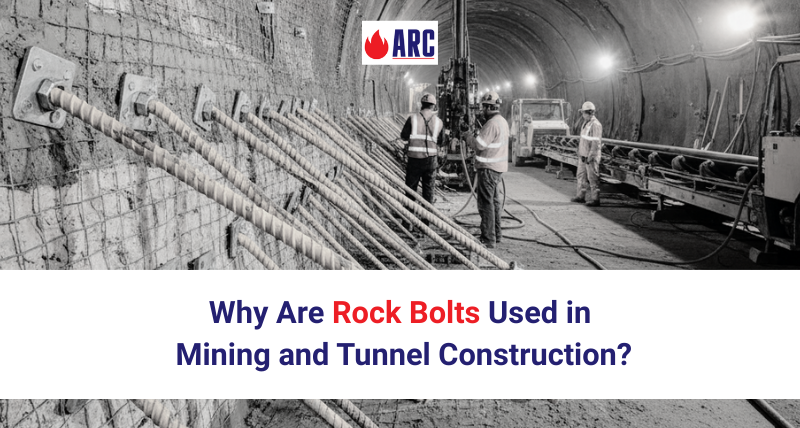

The underground construction sector is both volatile and vulnerable, dealing with various unique challenges. In the past, when there were no reliable ground support systems, the mining and tunneling industries struggled with frequent collapses and rockfalls, leading to major accidents and even life loss.

It wasn’t until the late 19th century that steel rock bolts were introduced, bringing a revolution in safety while mining and tunneling. Over the years, technologies have advanced, and GFRP (glass fiber reinforced polymer) rock bolts are now leading the era, in terms of safety, durability, strength, and longevity.

Let us explore the mechanics of rock bolts, their advantages, and why they remain the go-to support system in complex underground environments.

Traditionally, rock bolts are these long, steel-threaded rods inserted into drilled holes in rock formations to stabilize underground excavations. GFRP rock bolts are an alternative to steel ones. These are made of glass fiber and polymer which are resistant to corrosion, unlike steel which easily rust when exposed to moisture.

Once anchored, rock bolts exert tension and create a composite structure in which the rock mass and the bolt work together to distribute and resist loads. The primary principle of this reinforcement is pre-stressed anchorage.

The surface layers in a mine or tunnel can be unstable. The bolt transfers tensile forces from unstable surface layers to more stable interior strata. As a result, the rock itself becomes part of the support system, enhancing its natural ability to resist deformation and collapse. This interaction between the bolt and the surrounding rock mass is what makes rock bolts such a reliable solution in underground engineering.

The geographical condition of each tunnel or mine is not the same. Some have soft soil, or fractured rocks while other mines may have groundwater ingress and shifting fault lines. It is essential to understand the environmental conditions to install a support system.

Without proper support systems, tunnels can cave in under the pressure of surrounding materials or water seepage. This not only halts operations but also puts lives at risk. That’s why engineers have developed several tunnel support methods, each suited to specific geotechnical scenarios.

Here, we’ve shared the main methods before focusing on the strengths of GFRP rock bolts:

During mining or tunneling, miners used to apply shotcrete or sprayed concrete directly to tunnel walls. This is a mixture of cement, sand, aggregates, and water projected at high velocity through a nozzle to create a quick-setting lining.

The process forms a protective shell over the rock, providing immediate support while reducing dust and moisture infiltration. As the support system is very fast and flexible, it is the first choice in irregular tunnel geometries.

Steel mesh is often used in conjunction with shotcrete. After installing it in the tunnel walls, it helps hold loose rock fragments in place. In fractured rock conditions, debris and loose rock often cause minor and major injuries. This support method prevents debris from falling and adds a layer of reinforcement.

When tunneling, there are scenarios that require larger openings. Steel arches are installed to support the structural integrity of the tunnel, so it does not collapse. These elements redistribute loads and reinforce weak zones, especially in large tunnels with wide spans. The arches have high load-bearing capacity making them ideal for projects that pass through difficult terrain.

GFRP rock bolts are versatile supports used for various types of mining and tunneling projects. They stabilize the rock mass from within by binding loose or fractured rock layers to more stable zones.

Safety always comes first in underground construction. The unpredictable geological conditions are always a major concern. GFRP rock bolts come in various types. The expendable ones, especially, are very helpful for mining and tunneling.

Here’s why they are always a reliable choice:

Introduced in the 19th century, rock bolts have been a stable support system for mines and tunnels for around two decades now. They have gone through several evolutions offering smarter and more efficient ways to stabilize geotechnical structures.

For instance, GFRP rock bolts with adaptability, strength, and ease of installation. Their ability to turn fragile rock into a strong foundation makes them an indispensable tool for engineers and contractors alike.

GFRP (Glass Fiber Reinforced Polymer) rock bolts are corrosion-resistant, lightweight, and have higher tensile strength than steel, making them more durable and suitable for harsh underground conditions.

Rock bolts transfer tensile forces from unstable outer rock layers to stable inner strata, creating a reinforced structure where the rock and bolt work together to resist collapse.

They are corrosion-resistant, easy to install, adapt to various ground conditions, and compatible with other support systems like shotcrete and steel mesh.

Yes, GFRP bolts are often used with shotcrete, steel mesh, and steel arches to form a multi-layered, reliable tunnel support system.

Leave a Reply