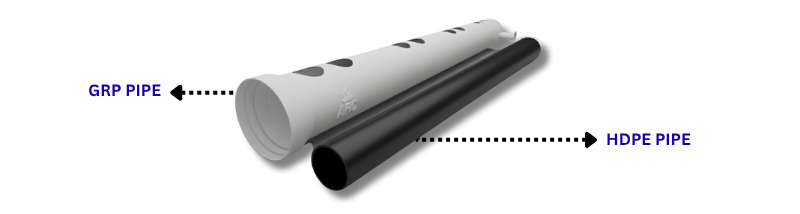

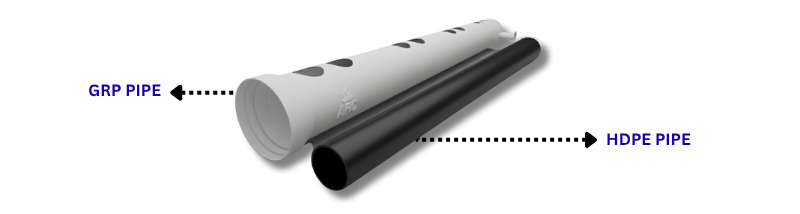

In infrastructure and industrial projects, each material holds a crucial position. Thus, it becomes essential to pay attention when choosing them, and piping material is no exception. Choosing the right pipe is critical for long-term performance, safety, and cost-efficiency. GRP (Glass Reinforced Plastic) pipes and HDPE (High-Density Polyethylene) pipes are some of the most popular materials in the present day.

Be it supplying water, drainage systems, or transferring industrial fluid, these pipes increase efficiency and safety. When you compare them in terms of material composition, performance, installation requirements, and lifecycle value, they vary significantly.

This article shares a clear comparison of GRP and HDPE pipes, so you can pick what suits you the best:

GRP (Glass Reinforced Plastic) is a composite material. The pipes are manufactured using fiberglass and thermosetting resins. The fibers add structural strength, while the resin matrix increases its chemical resistance and durability.

Also known as, FRP (Fiber Reinforced Plastic) pipes are internally diameter (ID) controlled, which helps maintain consistent hydraulic performance throughout their service life. Plus, these pipes are engineered according to the pressure, temperature, and load requirements of the specific project.

Here are a few special characteristics of Glass Reinforced Plastic pipes

HDPE (High-Density Polyethylene) is a thermoplastic polymer pipe. Known for their toughness, chemical resistance, and flexibility, the pipes are used for:

HDPE pipes are highly durable, and theoretically, they can live up to 100 years. However, practical life spans are often shorter depending on where they are used and their environmental exposure.

GRP and HDPE pipes are vastly different from each other. Here, we have explained each on a point-by-point basis:

As we already mentioned, glass-reinforced plastic is a composite of glass fiber and resin. Specially engineered to meet liquid type, burial depth, temperature, and pressure, they are durable and corrosion resistant.

High-Density Polyethylene on the other hand is a single thermoplastic polymer. It is manufactured using an extrusion process. The ability to withstand pressure for these types of pipes is generally defined by the wall thickness.

Glass fiber reinforced plastic pipes are available in a wide range of diameters, from DN 25 mm to DN 2600 mm. The manufacturing process of these pipes adds greater control over internal diameters (ID) with consistent hydraulic performance. This minimizes friction loss throughout the pipeline.

HDPE pipes are manufactured with external diameter (OD) as the controlling parameter, available from DN 20 mm up to DN 1600 mm. The length of these pipes may vary depending on the application. Smaller diameter pipes are used in irrigation while larger diameter pipes help with transporting large volumes of liquids and gases over long distances.

If needed, it is possible to custom-engineer FRP pipes up to 50 bars with a working pressure of up to 30 bars. For oil & gas applications it is even higher up to 2000 psi.

The pressure in HDPE pipes is connected to the wall thickened. The pipes are available in PN (pressure nominal) 6-16.

FRP boasts a modulus of elasticity (Ec) of 20,000 MPa, indicating high tensile strength and stiffness. This property makes GRP suitable for load-bearing applications, long-span installations, and high-pressure environments.

HDPE pipes, on the other hand, have a lower tensile strength with a modulus of elasticity of approximately 32 MPa. While HDPE is flexible and resistant to cracking under normal conditions, it is not as structurally robust as GRP in high-load or deep-burial scenarios.

There are several types of joining techniques for glass-reinforced plastic pipes such as

Did you know that FRP pipes are lightweight? Like around 1/4th of steel. These characteristics actually cut down installation costs more than steel or HDPE pipes. Even though they are rigid, their joint flexibility is particularly beneficial in seismic regions.

While HDPE is also relatively light, its installation costs can be higher. These pipes are suitable for water-tight applications such as water treatment or containment.

When using FRP pipes, it is essential to handle them carefully as surface damage can impact their performance. But on the bright side, these pipes are fully UV protected, so sunlight can’t affect their structural integrity.

HDPE pipes have inherent impact resistance. These pipes are also UV-resistant but to an extent. So, if they are in exposure to sunlight for a long period, it can cause material degradation as time passes.

Pipes generally carry liquids, including water, oil, and other chemicals depending on the application. Therefore, being prone to corrosion can be a major drawback.

Both FRP and HDPE do not require internal coatings and are inherently resistant to corrosion. Their exclusive properties make them suitable for aggressive and saline environments.

When choosing a pipe, most people generally consider the cost-effectiveness. FRP pipes are much cheaper than HDPE ones. Not only that, the price of HDPE pipes increases depending on the oil price, which does not have an impact on Glass Reinforced Plastic pipes.

When you consider the application, budget, and environmental conditions, both GRP and HDPE pipes bring distinct advantages to the table. FRP stands out for its strength, stability to UV radiation, seismic flexibility, and cost-effectiveness for larger diameters. HDPE, on the other hand, is renowned for its chemical resistance, ease of modification, and flexibility. So, before making a purchase, why do you need the pipes? If you still feel confused, consider speaking with a professional.

Read more on: Why Are GRP Pipes The Ideal Solution For Corrosive Environments?

Q.1. Are GRP pipes UV resistant?

Yes, FRP pipes have built-in UV protection and retain strength even when you leave them in the sun for a long time, unlike HDPE which may degrade over time if not protected.

Q.2. What kind of joints are used in GRP and HDPE piping?

GRP pipe systems use push-fit, flange, and laminated joints. HDPE pipes use butt fusion, electrofusion, and compression fittings, offering leak-proof and flexible connections.

Q.3. Which pipe type is more cost-effective for large infrastructure projects?

GRP pipes are generally more cost-effective for large-diameter projects due to lower material and installation costs compared to HDPE pipes of similar size.

Q.4. Can HDPE pipes handle the same pressure as GRP pipes?

No. GRP pipes can be custom-engineered for higher pressure (up to 50 bar or more), while HDPE pipes typically come in PN 6–16 ranges depending on wall thickness.

Monsoon can be complicated. Especially when the water management system is not designed for the season. Monsoon rains bring heavy downpours that test drainage systems. Floodwaters and waterlogging are common when streets and drains cannot keep up with the volume of rain. In saturated ground, even minor shifts can damage or misalign buried pipes. There […]